Building Quality Through Every Process

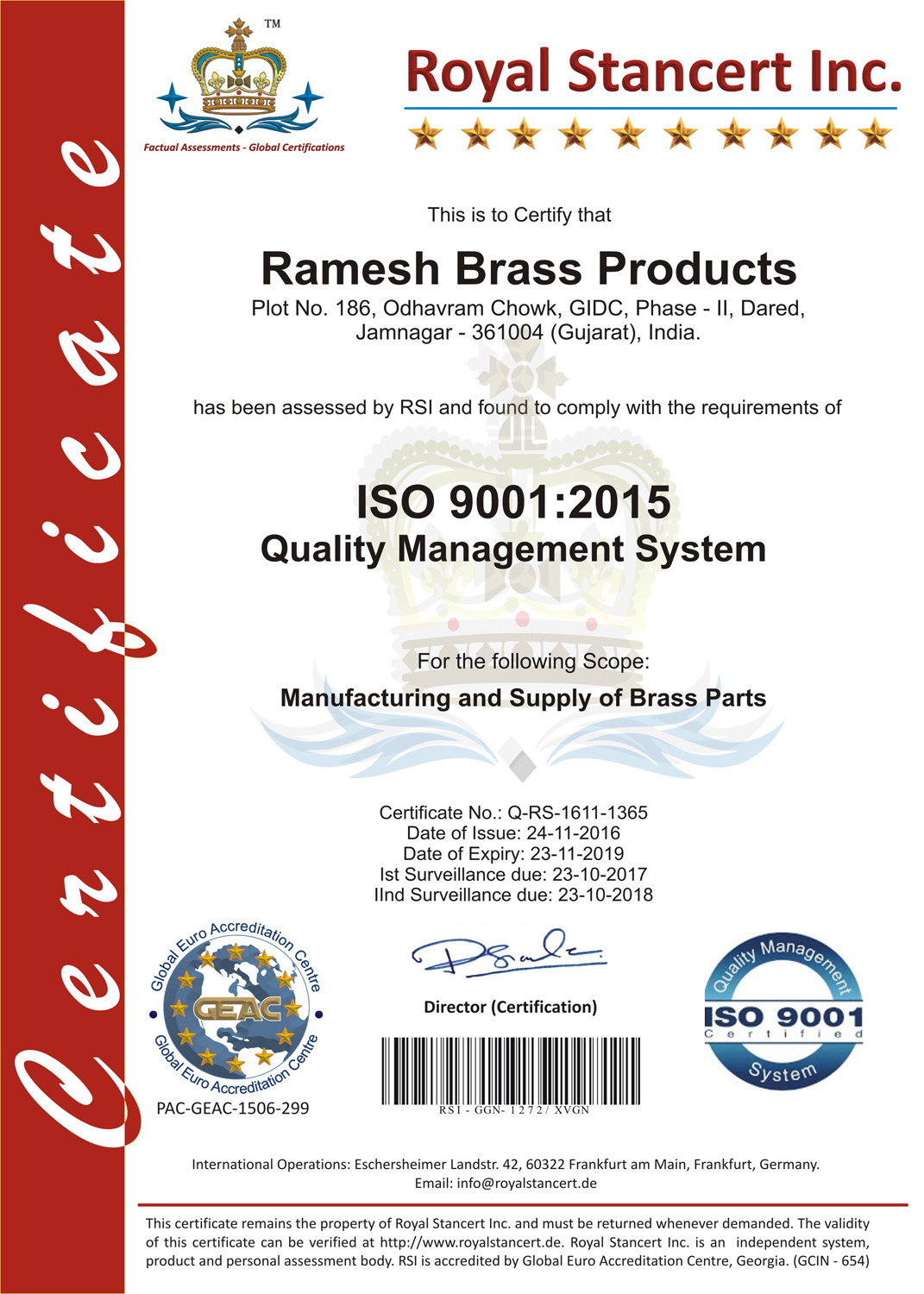

At Ramesh Brass Products, quality is the foundation of every operation we perform. Our approach to quality assurance is proactive and process-driven, ensuring that excellence is embedded at every level of manufacturing rather than inspected in at the end. From the moment raw materials enter our facility to the final stage of dispatch, each component is subjected to detailed monitoring, precision checks, and performance validation. This systematic control allows us to maintain consistency, reliability, and compliance with global standards across all product categories.

We believe true quality lies in continual improvement. Our team regularly reviews processes, upgrades equipment, and integrates innovative inspection techniques to enhance efficiency and precision. Every team member is trained to uphold our quality philosophy, delivering products that not only meet specifications but also earn customer confidence through proven performance, durability, and integrity.

Zero-Defect Commitment

Every unit is manufactured with the goal of achieving absolute precision and reliability.

Process-Oriented Approach

Quality is built into each step rather than verified only at the end.

Advanced Testing Infrastructure

Equipped with precision instruments for mechanical, visual, and dimensional inspection.

Experienced Quality Engineers

Skilled professionals ensure adherence to specifications and continuous process validation.

Full Traceability

Detailed records of materials and production batches are maintained for accountability and transparency.

Feedback-Driven Refinement

Regular customer and process feedback help us evolve and strengthen our quality systems.